Whatever It Takes for an Efficient Fleet

?MAINTENANCE & REPAIR

Whatever It Takes for an Efficient Fleet

?MAINTENANCE & REPAIR

PERFORMANCE

The performance and availability of your industrial trucks are essential in guaranteeing their productivity. Linde ensures maximum performance through proactive maintenance, quick repairs on-site and the provision of replacement trucks, where necessary.

OPERATING COSTS

The precise planning of all service measures by Linde’s in-house staff and compliance with service intervals save time and money. Linde service technicians also detect the initial signs of damage and know which preventative measures to take. This enables consequential damage to be reduced and unnecessary repairs to be avoided. The warranty is also retained and the resale value increases.

SUSTAINABILITY

Sustainability is another important Linde service factor. Resource consumption is reduced thanks to efficiently controlled service and the longest possible servicing intervals. This benefits people, the environment, and companies alike.

SAFETY

The safety of man and machine is the utmost priority. The manufacturer service allows companies to reduce their operational and legal risks. Linde service technicians are not just familiar with the maintenance requirements, but also the applicable legal provisions, and they provide seamless service documentation.

To ensure that industrial trucks support operational procedures efficiently, they must first and foremost be continuously available. This is where Linde Material Handling provides support with maintenance and repair services. Our highly qualified service technicians ensure compliance with service intervals, and quickly and reliably service and repair over 300 types of trucks.

Besides the best possible truck and fleet availability, companies can also rest assured that they are on the safe side when it comes to occupational health and safety. Regular servicing also reduces the operating costs and increases the resale value of industrial trucks. Depending on the specific customer requirements, Linde offers perfectly tailored service packages, from rapid repairs through to full service contracts.

The extensive service network with around 8500 service technicians worldwide means that we are always close to the customer. Linde provides round the clock support, seven?days a week. This means that your forklift trucks and warehouse handling equipment remain productive and safe, and your operations are consistently cost-effective and sustainable.

REPAIR SERVICE

Rapid Assistance in Case of Damage, Wear, or Conversion Requirement

Whether through multi-shift operation or harsh operating conditions, great demands are placed on industrial trucks. Extreme environmental influences, such as when used in foundries, cold storage houses, the fishing industry, and sectors with a high dust exposure, may also accelerate the appearance of wear and tear. If particularly intensive use or a lapse in concentration on the part of the driver lead to damage to the truck, Linde Material Handling provides fast and reliable support, even if no maintenance contract is in place. One call to the service hotline is all it takes and a technician will be on their way with the required original spare parts. The extensive Linde service network guarantees quick response times and constant availability.

Conversion and Retrofitting for Special Requirements

The challenges faced in everyday logistics operations don’t just include wear and repairs. The operating conditions for industrial trucks may change, for instance due to new logistics processes, changed infrastructure on the company premises, or higher safety and comfort requirements. In these cases, a minor conversion or simple retrofitting by Linde is sufficient. To make sure that operation continues without interruption, even in the event of major conversions, Linde supplies replacement forklifts from the largest rental fleet in Europe.

REGULAR SERVICING

PREVENTIVE TO MINIMIZE FAILURE AND REPAIR COSTS

Ideally, industrial trucks should not require repairs in the first place. After all, apart from damage due to accidents, most repairs on warehouse handling equipment or forklift trucks are due to continuous use, i.e., due to entirely normal wear and tear. In particular, major repairs can be avoided, if wear is promptly detected, minimized, and prevented.

MATCHING SERVICING INTERVALS

Detect damage and leaks, check the brake system and the steering system, replace the hydraulic oil: As part of corresponding servicing contracts, Linde service technicians can promptly identify wear and take the necessary measures. The servicing intervals are defined by the manufacturer’s specifications and are adapted to the specific truck in the event of an increased workload. The Linde service team coordinates the servicing deadlines with the regular safety checks, such as emissions tests. This means that companies can also satisfy the legal requirements, all in a single step.

SEAMLESS CHECK THANKS TO STATE-OF-THE-ART DIAGNOSTICS

Powerful control technology, as used in the automotive industry, also allows industrial trucks to be analyzed quickly and reliably. In addition to regular maintenance, this also allows the Linde service technician to suggest preventative measures to avoid costs for unplanned failures and short-term repairs.

Regular servicing ensures that all forklifts are operational for the long term, and that downtimes and repair costs are reduced

FULL SERVICE

Comprehensive and Straightforward: Minimize the Risk of Failures with Maintenance Contracts

Anyone wanting to have as little to do with servicing and repairs as possible, while simultaneously wanting maximum truck availability, will want a full service contract. This lets you place all the necessary activities, from planning and coordination through to professional implementation and seamless documentation, into the professional hands of Linde service employees and highly qualified service technicians. Regardless of whether it relates to maintenance deadlines, repairs, the procurement of spare parts or safety checks, the full service contract comprehensively covers all the necessary maintenance measures.

Tailored to Customers’ Requirements

Companies can select the right contract from a range of variants depending on their requirements. Moreover, there are numerous options to customize the full service contract to suit specific customer wishes, such as defined response and repair times, permanent assignment of service technicians for on-site fleet management, and the management of the entire battery management system. Full service contracts are worthwhile irrespective of the number of industrial trucks in use. After all, seamless operation and the lowest possible internal expense for servicing and repairs lie at the heart of every efficient operation.

Optimal Service Planning

Continuous servicing enables a significant reduction in costly repairs. However, if repairs do still arise, Linde effectively integrates their planning in the production process in advance and logically combines service jobs so that downtimes are kept to a minimum. This also allows regular servicing activities to be coordinated. This, in turn, reduces downtimes and saves costs.

Battery Regeneration

At Linde, we provide battery regeneration to allow our customers to maximize their battery investment.

Benefit

Financial Profit

- Maximise battery investment

- Minimise maintenance costs

Technical Advantages

- Battery life extension

Positive Environmental Impact

- Reduce battery waste

Benefits of Manufacturer Maintenance at a Glance

- Maximum availability and efficiency of trucks

- Early detection of any developing damage

- Consistent minimization of safety risks

- Reliable avoidance of unnecessary repairs and consequential damage

- Predictable and transparent costs for maintenance and servicing

- Guaranteed compliance with warranty conditions

- Reliable service documentation

- Significant increase in the resale value of trucks

Chassis, bodywork & fittings

- ?Check that the adjusting mechanism on the steering column is secure

- ?Check the condition of the operator‘s seat and seat belt: secure, excessive wear, damage

- ?Check the tyres and rims: profile, external damage, air pressure

- ?Check drive system and steering: smooth control, responsive to command

- ?Test service brake and parking brake

- ?Check the level in the washer system reservoir

Engine / Battery and Chargers

- Diesel: Check fuel level, do not overfill

- LPG: Check fill level in the LPG system. Check that the console of the LPG tank is correctly positioned

- LPG: Carry out a visual and odour inspection on the LPG system

- Check engine oil level, caution when hot

- Check cooling fluid level, never when hot

- Check truck for leaks

Battery and Chargers

- Check the state of charge of the battery

- Check the electrolyte level, topping up with distilled water if necessary

- Check that the battery poles are tightened, cleaned, and lubricated

- Check the battery and charger connections

Hydraulics and Fluids

- Check the oil level in the hydraulic system

- Check the truck for leaks (visual control), e.g. transmission, steering, working hydraulics

Electrics

- Check the electrical system, e.g. lights, beacons, warning units, wipers

- Trucks with LSP: make sure that correct attachment is selected in LSP.

Load Lift System

- Check fork arms and fork latches: correctly fitted, undamaged

- Check that the attachments are working correctly. Observe the manufacturer‘ s operating instructions.

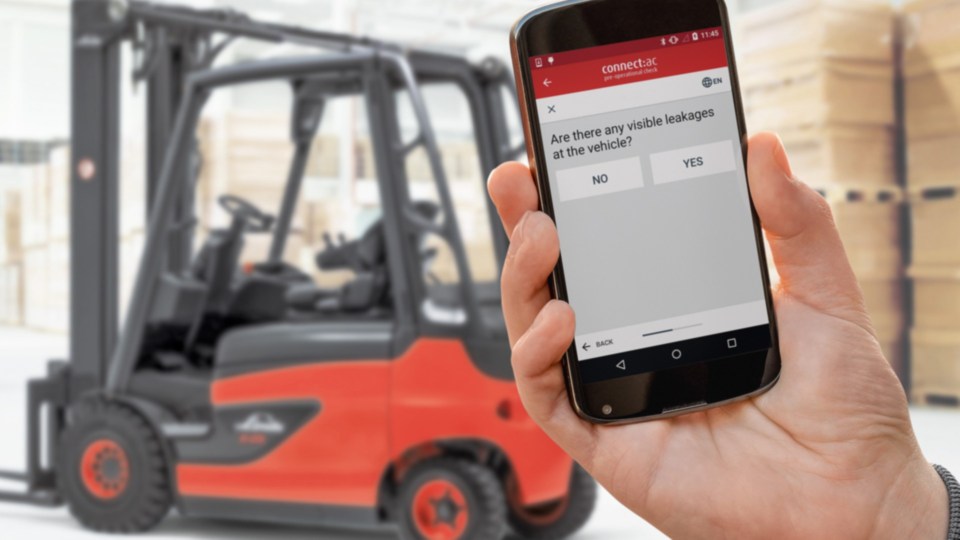

The Electronic Pre-operational Check

If your drivers are equipped with a smartphone, the Linde Material Handling “pre-op check” app provides assistance in performing daily safety checks. It enables your drivers to simply use their smartphone or tablet to check that a forklift is fit for use. Instead of using a paper form, the logistics employee responds to questions on the truck status on the touchscreen. Only once the test has been successfully passed can the forklift or warehouse handling equipment be used, making this a simple and expedient measure for improved safety and performance.